Automatic CNC Vertical Insulating Glass Machine Insulating Glass Production Machine with CE

Overview Package Size 930.00cm * 250.00cm * 370.00cm Package Gross Weight 7000.000kg Product Description Vertical Automa

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | LBW2500PC |

| Structure | Vertical |

| Control System | PLC |

| Glass Washing Machine Type | Vertical Glass Washing Machine |

| Condition | New |

| After-sales Service | Provided |

| Application | Making Insulating Glass |

| Min Glass Size | 350X350mm |

| Coulor | Can Design It as Customer′s Demands |

| Max Glass Size | 2500X3500mm |

| Washing Glass Thickness | 3-19mm |

| Igu Glass Thickness | 60mm |

| Transport Package | Wooden Box&Plywood Pallet&Plastic Film |

| Specification | LBW2500PC |

| Trademark | WGM |

| Origin | China |

| HS Code | 84649019 |

| Production Capacity | 600-700sets/8hours |

Packaging & Delivery

Package Size 930.00cm * 250.00cm * 370.00cm Package Gross Weight 7000.000kgProduct Description

Product Description

Vertical Automatic Insulating Glass Outside Assembly Flat Press Production Line is a high-efficiency insulating glass processing equipment. This line can not only produce ordinary insulating glass but also for low-e insulating glass. It is a better mass production equipment to produce insulating glass with high automatic degree, high efficiency, easiness of operation and maintenance.1.Adopts the Omron PLC to control the working condition,touch screen and man-machine interface.2.Low-E glass automatic diagnosis system.3.Cleans coating glass and Low-E glass.4.Adopts no oil water-proof bearing in the washing section.5.Conserves energy interrupted type automatic operation system6.produce double glazing ,triple glazing and Low-E glazing,stepped glazing is optional7. Achieve the function of outside and inside asembly , automatic filling argon gas and stepped glazing.8. Adopts the PLC to control the working condition and youch screen.9.Automatic detact coated surface of coating glass and LOW-E glss.10. Air knife can automatic adjust according to glass thickness.11. Brushes's rotate speed variable frequency drive.12. Aluminum spacer and glass automatic positioning system.13. Automatic detect the length and height of glass , automatic adjust the best gas filling time.14. Automatic gas filling press machine adopt 4 servo motors, which has assembling , pressing and automatic.15. It has remote monitor and program upgrade fuctions.

Product Parameters| Power Supply | 380V 50 HZ 35KW |

| Dimension (L x W x H) | 25410x2800x3450 |

| Production quantity | 600-700IG units/8hs |

| Max glass size | 2500mmx3500mm |

| Min glass size | 300mmx400mm |

| Washing glass thickness | 3-19mm |

| Washing glass speed | 0-10m/min |

| Insulating glass thickness | 60mm(can adjust) |

| Transmission glass speed | 45m/min |

| Compress air | 0.8m³/min |

| Air pressure | 0.8Mpa |

| Argon gas percent | ≤90% |

| NO. | Name | Brand | Brand Place |

| 1 | PLC | SCND | FRANCE |

| 2 | 10.0 inch touch screen | SCND | FRANCE |

| 3 | Photoelectric switch | AUTONICS | KOREA |

| 4 | Limit switch | AUTONICS | KOREA |

| 5 | Transducer | SCND | CHINA, FRANCE |

| 6 | Low voltage electric components | SCND | FRANCE |

| 7 | Solenoid valve | AIRTAC | CHINA, TAIWAN |

| 8 | Cylinder | AIRTAC | CHINA, TAIWAN |

| 9 | Liner guide rail | PMI | CHIAN, TAIWAN |

| 10 | Servo motor | SIMENS / SCND | GERMANY |

| 11 | Transmission motor | DPG | CHINA |

Answer:

Yes,we are the professional insulating glass processing machines manufacturer, which has 21-years history since 2001.

and in order to export easily,we build the trading company

Answer:

1).Timely reply it at once on WhatsAPP and Email.

2).18 hours online for after-sale service

4).more than 21 years experience in this kind machine field

5).fluent English ,communication barrier free. Point-to-point service help you solve the problems timely.

Answer:

1). Our guarantee for 12 months.

2). 18 hours' technical support by email, video or calling

3). English manual and video tutorial

4). 24 hours on line service each day, free professional technical support.

Answer:

A: Yes. Based on the situation stable and policy allowed, we can will send one or two professional technicians (one is electrical engineer, one is mechanical engineer) to install and adjust the machines and help train the workers.

Answer:

1) We are a innovative enterprises, not only a produce factory. We have a a professional and experienced technical elite team. Every year we will apply for innovation patents for our insulating glass machine, likes auto gas filling machine, auto loading machine and etc.

2)Compared with the same level brand, we have the same functions and components, but our price is the most competitive. At the same time, our after sales service is satisfactory. We have a good reputation in our customers.

Related Products

-

![Zamak Material Nice Touching Washroom Privacy Door Lock for UPVC Door]()

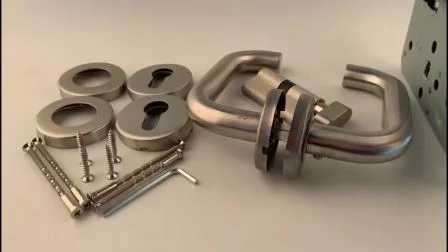

Zamak Material Nice Touching Washroom Privacy Door Lock for UPVC Door

-

![Aluminum Window Door Machine /Window CNC Cutting Machine/Double Head Cutting Saw Machine with Good Price]()

Aluminum Window Door Machine /Window CNC Cutting Machine/Double Head Cutting Saw Machine with Good Price

-

![UPVC/PVC Window and Door Plastic Profile/Door Frame/Ceiling Panel Extrusion Machine]()

UPVC/PVC Window and Door Plastic Profile/Door Frame/Ceiling Panel Extrusion Machine

-

![Double Glazing Press Production Line Automatic Insulating Glass Machine Insulating Glass Online Gas Filling]()

Double Glazing Press Production Line Automatic Insulating Glass Machine Insulating Glass Online Gas Filling